3M™ LifeASSURE™ PFS Series Filter Cartridge, PFS020A01BK, 10 in, 0.2 um,226/Spear, PTFE, 6/Case

About the product

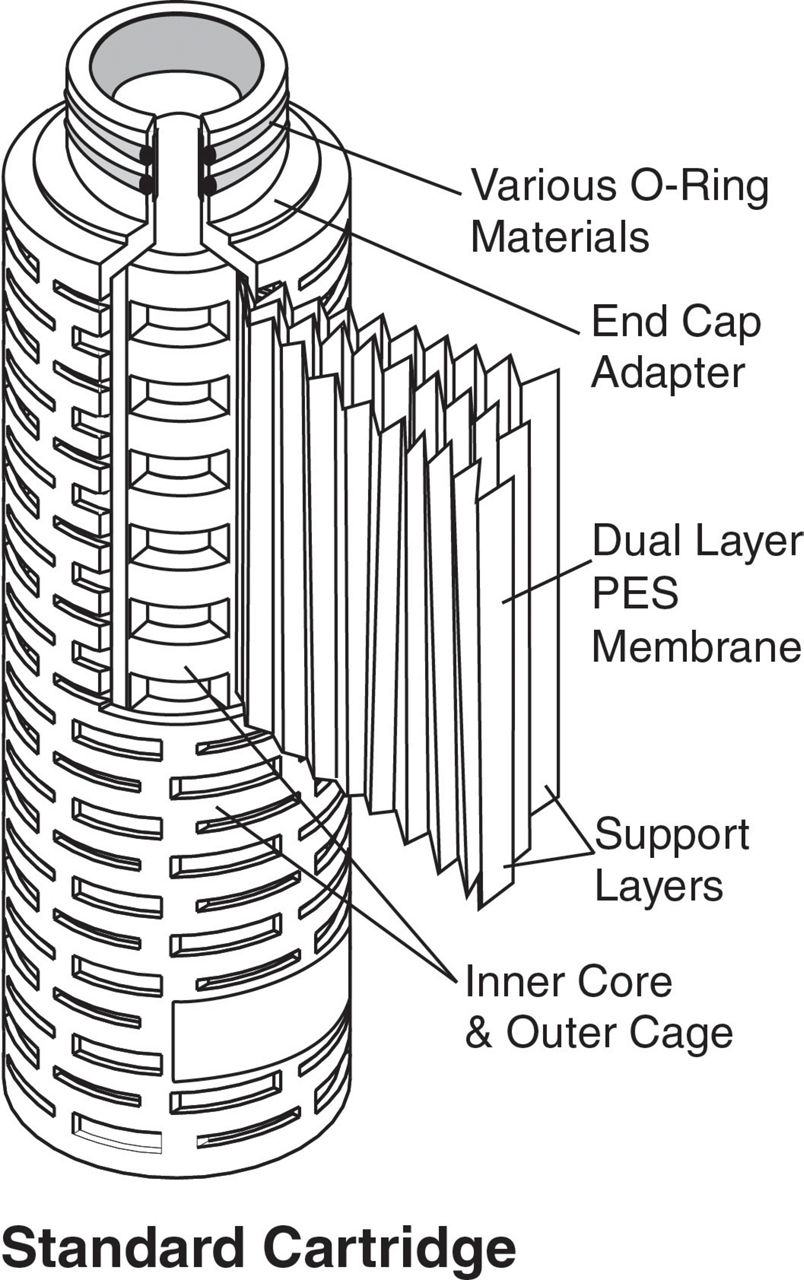

Our LifeASSURE™ PFS Series PTFE Filter Cartridges combine flow-enhancing construction with a liquid‐validated, bacteria retentive, hydrophobic PTFE filter membrane, providing excellent air flow rates using small assemblies. Our filters are used for applications requiring 0.2 micronsterilization of air, gas, solvents and chemicals in life science industries.

Product Details

- Flow-enhancing construction allows air flow with a relatively low pressure drop, resulting in a smaller vent filter assemblies

- Hydrophobic polytetrafluoroethylene (PTFE) membrane helps prevent pore blockage in vent applications, extending filter lifespan

- Liquid validation of B. diminuta retention helps provide reliable sterilizing performance in wet or dry conditions

- 100% forward flow integrity tested prior to release

Product Specifications

| Industries |

Industries

Biopharmaceutical manufacturing |

| Product Form |

Product Form

Cartridge |

| Filter Technology |

Filter Technology

Membrane |

| Micron Rating (Absolute) |

Micron Rating (Absolute)

0.2000 |

| Product Series |

Product Series

PFS |

| Grade |

Grade

PFS020 |

| Brand |

Brand

LifeASSURE™ |

| Overall Length (Imperial) |

Overall Length (Imperial)

10.0000 |

| Overall Diameter (Imperial) |

Overall Diameter (Imperial)

2.7600 |

| Overall Length (Metric) |

Overall Length (Metric)

25.4000 |

| Product Type |

Product Type

Pleated Membrane |

| Overall Diameter (Metric) |

Overall Diameter (Metric)

7.0000 |

| End Modification |

End Modification

226 O-ring & Spear |

| Filter Type |

Filter Type

Surface |

| Application |

Application

Sterile filtration |